- Home

- Our Company

- Why Us

.png)

- Quality Control

- R&D

.png)

- Production Capability

- Products

.png)

- LED Work Light Housing

- Wheel Chair Parts

- LED Lighting Housing & Heat Sink

- Telecom Parts Heatsink Housing

- Aluminum Furniture Parts

- Lighting Industry & Fixtures Components

- Die Casting Motor Housing

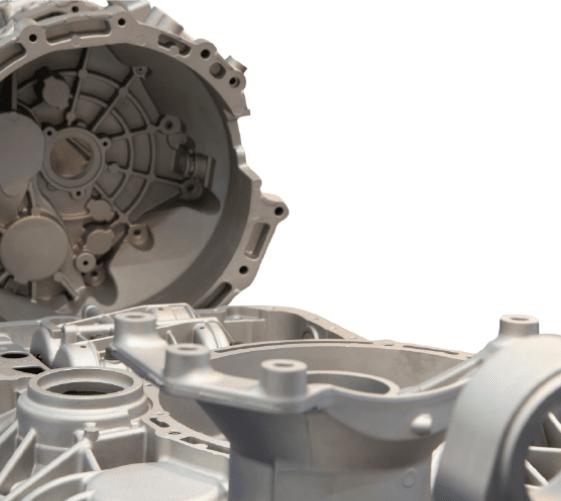

- Automotive Casting Components

- Water Heater Components

- Precision CNC Machining Components

- Mechanical Products

- Automotive Led Heat Sink

- Aluminum Hydraulic Housing

- CNG Valve Parts

- News

.png)

- Contact Us

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)